Our Products

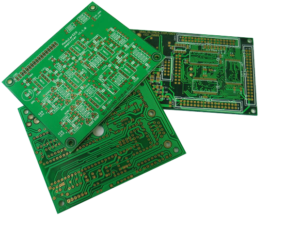

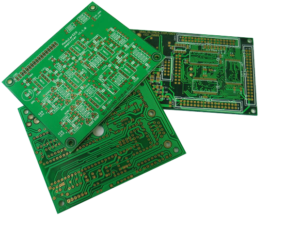

Rigid PCBs

These PCBs are made from solid substrates that prevent it from twisting. PCBs can be single-sided, double-sided, or multilayer. Multilayer PCBs allow for much higher components density, because circuit traces on the inner layers would otherwise take up surface space between components. The rise in popularity of multilayer PCBs with more than two, and especially with more than four, copper planes was concurrent with the adoption of surface mount technology.

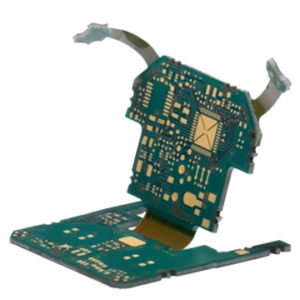

Rigid-Flex PCBs

These are hybrid printed circuit boards that feature a combination of both rigid and flexible materials. Rigid-flex PCBs are well-known for their weight and space reduction capabilities. At present rigid-flex PCB is applied in more and more application, as it can offers optimum solutions for limited installation space conditions and also rigid-flex PCB can provide the possibility of secure and high electrical connection performance of the device components with the assurance of contact stability, as well as a reduction in plug and connector components.

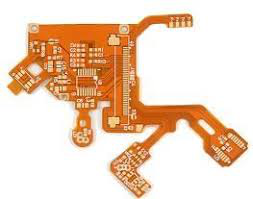

Flexible PCBs

A flexible PCB is an arrangement of components and circuits that use various flexible based materials with flexible coverlay. Sometimes, these components and circuits are also assembled without flexible coverlay. These PCBs are popular because they are easy to assemble, and are lightweight. The flexible PCBs are also ideal for applications that require flexible material. These circuit boards can be availed in single-sided, double-sided and multilayer formats.

High Density Interconnect (HDI) PCBs

HDI PCBs capitalize on the latest technologies available to increase the functionality of PCBs using the same or less amount of area. This advancement in PCB technology is driven by the miniaturization of components and semiconductor packages that support advanced features in revolutionary new products. HDI PCBs are characterized high density attributes including laser micro vias, fine lines and high performance thin materials. This increased density enables more functions per unit area. Higher technology HDI PCBs have multiple layers of copper filled stacked micro vias (Advance HDI PCBs) which creates a structure that enables even more complex interconnections. These very complex structures provide the necessary routing solutions for today’s large pin-count chips utilized in mobile devices and other high technology products.

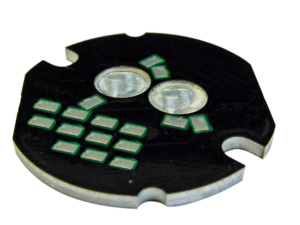

Metal Core PCBs (MCPCB)

These PCBs receive their name from metal bases, which serve as heat dissipaters. Base metal in PCBs are ideal alternatives to the regular CEM3 or FR4 circuit boards. These printed circuit boards have the ability to dissipate heat from the critical components, as well as from other less crucial area such as metallic core, and metal heatsink backing. The metal core PCB can be made from aluminium (aluminium core PCBs), copper (copper core PCB and heavy copper core PCB), and a mixture of several special alloys. The most common type of PCB is aluminium core PCB.

Technical Capabilities

Circuit Line offers a wide range of products, delivering a high degree of flexibility to meet the needs of different customers.

Please see the table below for an overview of our production Capabilities.

In case a specification or technology your require is not listed below, please do not hesitate to contact us.

| Layer Count

Finished Board Thickness Max.Production Panel Size Min. Line Width / Line Space ( Inner and Outer Layer ) Min. Hole Size Aspect Ratio Base Material (ShengYi, Nanya, KB, Ventec, ITEQ)

Copper Thickness Surface Finished

Solder Mask Color Legend Color Profiling Special Technology

|

– 1 ~ 24 layers

– 0.4mm ~ 3.2mm – 533mm x 635mm – 0.075mm

– 0.20mm – 10:1 – CEM 1 / CEM 3 FR-4 ( Normal TG & High TG ) Halogen Free ( RoHS compliance ) Rogers Metal Base ( AL / Cu etc. ) – Min.1/2oz. to max.5oz. – ENIG / OSP / Immersion Tin & Silver Hard Gold / Carbon Print / Resin Plugging HASL-Lead Free / Gold Finger Plating – Green (Matte/Glossy), Blue, Red, Yellow, Black – Black, White, Yellow – Routing, Punching, V-Scoring/Jump V-Scoring – HDI boards ( micro vias, buried vias )

|

| Layer Count – Rigid-Flex

– Flex Finished Board Thickness

Max.Production Panel Size

Min. Line Width / Line Space Drill Hole Diameter (min)

Laminate – Rigid – Flex

Outer Layer Bare Copper (min.) Surface Finished

Solder Mask Color Legend Color Profiling

Stiffener

|

– 2 layers ~ 24 layers

– 1 layer ~ 8 layers – Rigid-flex : 0.2~3.2mm – Flex : 0.15mm – 250mm x 1000mm (2L) 250mm x 500mm (ML) – 3mil/3mil (0.075mm/0.075mm) – 6mil (0.15mm) – Mechanical drill – 2mil ( 0.05mm) – Laser drill – FR4 / Halogen Free – PI CCL material / PET CCL material – Coverlay (PI & PET) – ¼ oz

– HAL-LF / ENIG / Immersion Tin & Silver Gold Finger / OSP / Carbon Print – Green / Yellow / Blue / Black / White Black / White / Yellow – Punching Laser Cutting Routing – PSA (pressure sensitive adhesive) TSA (thermal sensitive adhesive) Materials: FR4 / AL / PI / Ceramic |