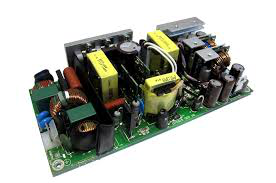

Printed Circuit Board Assembly (PCBA)

Using the most advanced equipment, highly skilled and experience personnel, and efficient processes, our off-shore facilities undertakes all its PCBA manufacturing process and operations in accordance with ISO9001/ ISO13485 / TS16949 / ISO14001 standards and in compliance with the IPC-A-600 and IPC-A-610 acceptability of Printed Boards Standards. We help our customers determine the appropriate level of test and execute according to customers order fulfilment model.

This allows us to offer our customers low-cost, One-Stop PCB Assembly Services, including PCB fabrication, parts procurement and PCB Assembly. This is an ideal service for PCB prototyping, as well as low volume and medium volume production runs, we verify all details of your files, including BOM (Bill of Materials) and Gerber files, to allow you to correct your PCB design before manufacture, saving significant time and cost, and avoiding unnecessary repeats of the prototyping assembly process.

PCBA Manufacturing Overview

- Full Turn-Key assembly

- Partial Turn-Key assembly

- Consigned assembly

- Prototype assembly

- PCB Fabrication

- Components Sourcing Services : 100% ensure all parts are original ones from authorized distributors.

- PCB Assembly : SMT , Through-Hole, BGA, QFP, QFN parts assembly

- ISO certified : ISO9001, ISO4001, TS16949, ISO13485, IPC-A-610, IPC-A-600 and UL

- RoHS compliant lead-free assembly

- Conformal coating

- Final box-build and packaging

- IC programming

- High density PCBA

- Flex and Rigid-Flex manufacturing on various finishes such as bare copper, OSP, ENiAg and ENiAu

- Oblique x-ray inspection for Failure Analysis

- High dielectric and controlled impedance

- Automatic precision components placement

- Automated and semi-automated plated through-hole (PTH) assembly

TEST

We offer complete functional test for variety of electronics, systems and devices. Our functional test services validate that products perform in accordance with customer expectations. Our test services offer all types of functional testing, ranging from standard test systems, PC-test systems and custom designed test systems.

We adopt a variety of testing methodologies to endure the assembled boards are functional prior to shipping.

- Basic Quality Test : Visual Inspection

- X-ray inspection : Test for BGA, QFN, QFP and bare PCBs.

- AOI Checks : Test for solder paste, 0201 components, missing components and polarity.

- ICT (In-circuit Test) / Functional Test : According to the customer’s testing procedures.